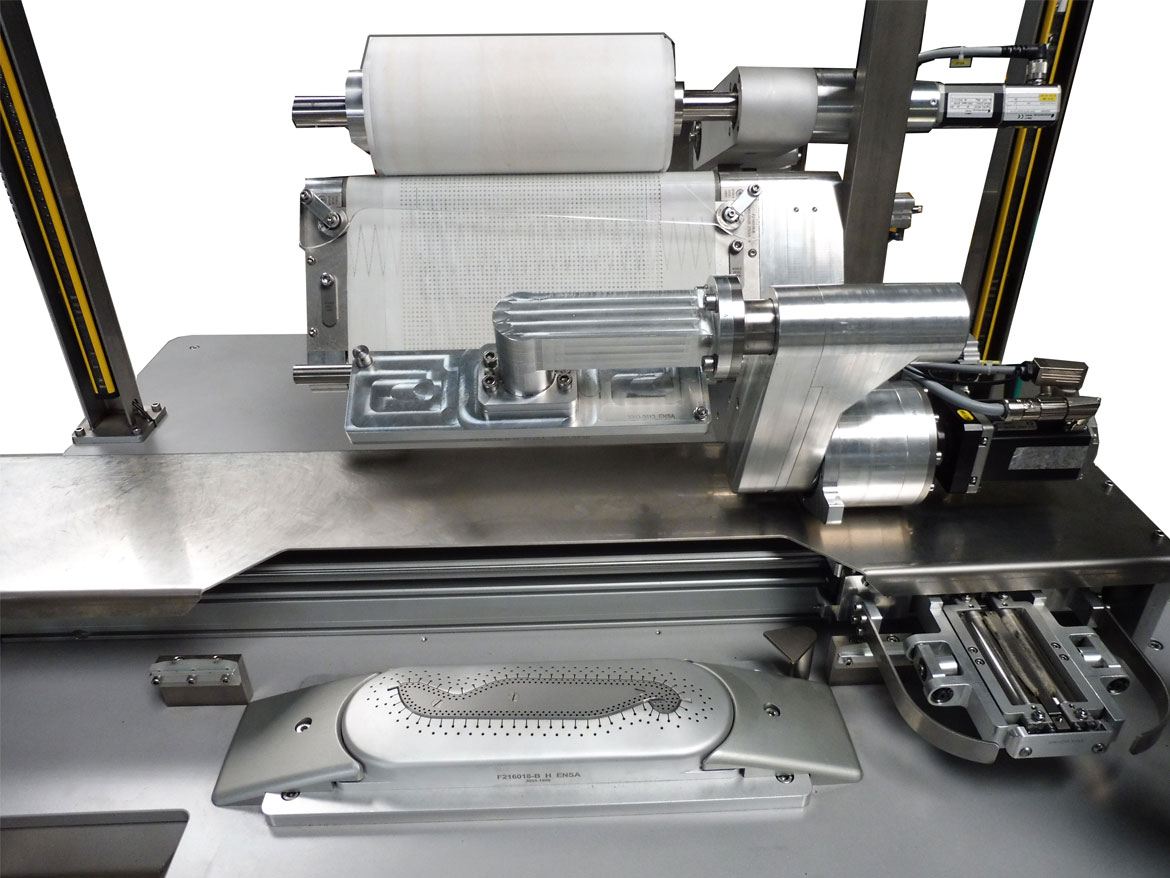

EBM

Research & Development is at the heart of our organisation. We translate market demands into new parts and machines. When the demand for “bobbin making machines” grew, we didn’t hesitate, we started developing them. We used the latest technology and most durable materials, of course, to optimise the machine even further.

LESS TIME, MORE PROFIT.

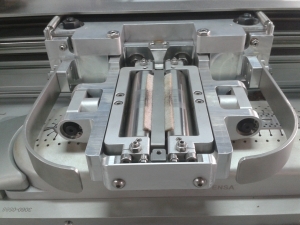

We took an existing bobbin machine as point of reference for the development of our EBM (Ensa Bobbin Machine) and completely re-engineerd it. We transformed a machine which was mainly composed of mechanical parts into a machine with many electrically driven movements. The advantages are that the machine is safer, less noisy and uses less energy. The bobbins are much better because the pinching at the cutters is negligible. The entire bobbin has a constant tension, all the way to the core! The result: no more hard bobbins! Apart from that, fewer cutters are missed when unwinding during production, and the technicians need less time to change over or adjust the machine.